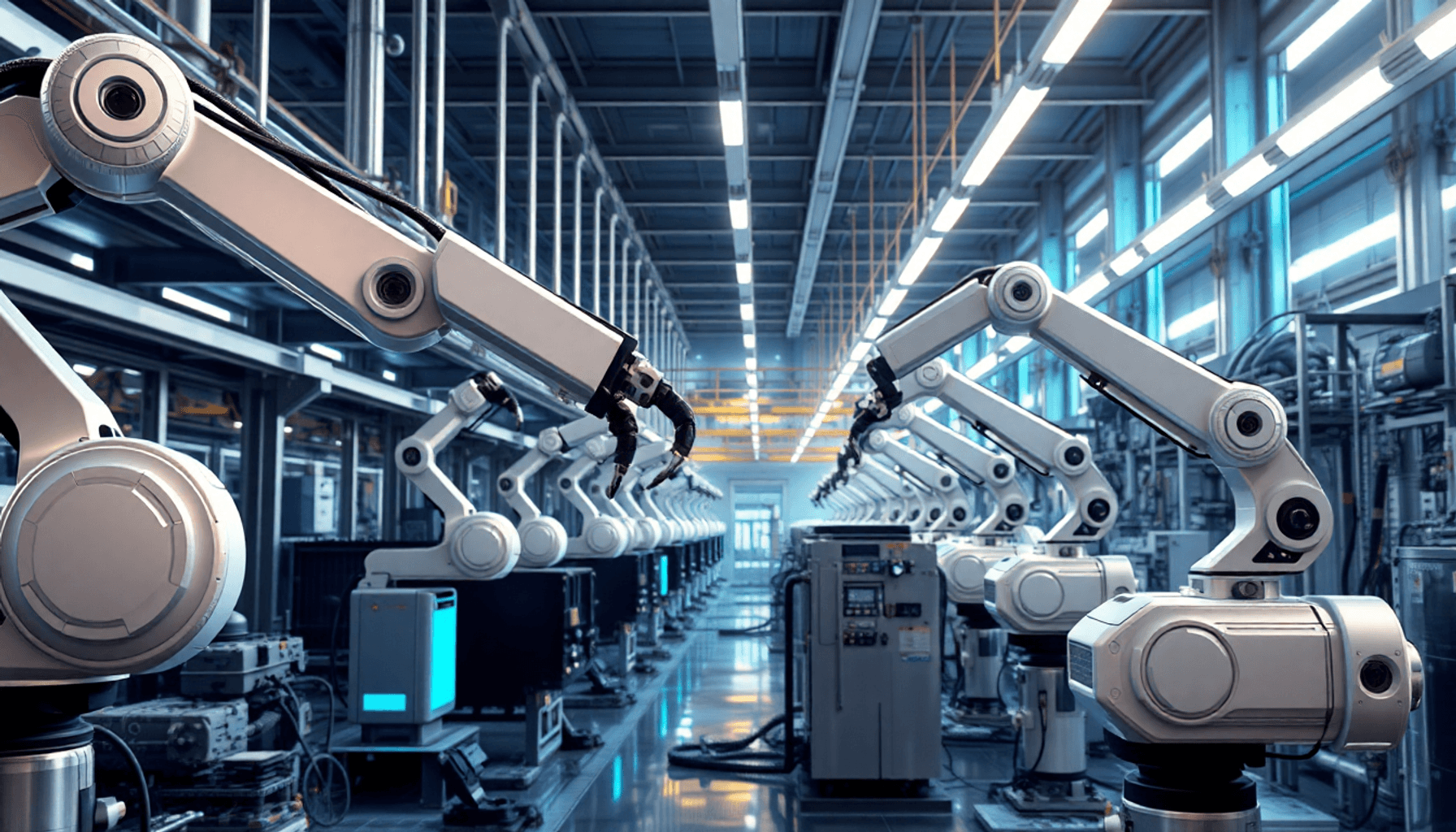

The manufacturing transformation driven by artificial intelligence is more than just basic automation. AI in manufacturing now looks at millions of data points from sensors and equipment, predicts failures before they happen, and improves production processes with incredible accuracy. These systems can find tiny defects that the human eye can't see, design products on their own, and manage complex supply chains with little human involvement.

What makes this revolution so surprising isn't just the technology itself, it's the unexpected ways manufacturers are using it. From robots working safely alongside humans to virtual replicas of entire production lines, AI factory automation is creating new possibilities that cut downtime by up to 50%, reduce waste, and speed up innovation. In this article, we'll explore applications that challenge traditional beliefs about what can be achieved in factories.

1. Enhancing Efficiency and Precision through Machine Learning

Machine learning algorithms are changing the way factories handle and respond to operational data. These systems constantly analyze information from thousands of sensors placed throughout production lines, finding patterns that human operators might overlook. The algorithms pick up on subtle connections between temperature changes, vibration levels, equipment speed, and product quality, and then automatically make adjustments to keep everything running smoothly.

Real-world examples of machine learning improving precision manufacturing :

- Semiconductor fabrication facilities use machine learning to monitor nanometer-level precision in chip production, reducing defect rates by up to 30% through real-time adjustments to etching and deposition processes

- Automotive paint shops employ algorithms that analyze humidity, temperature, and spray patterns to achieve consistent coating thickness within micrometers, eliminating costly rework

- Pharmaceutical manufacturers leverage machine learning to maintain exact ingredient ratios and mixing times, ensuring batch-to-batch consistency that meets stringent regulatory requirements

The machine learning approach in factories leads to measurable efficiency improvement by reducing cycle times and material waste. You'll witness production lines that optimize themselves based on past performance data, automatically fine-tuning conveyor speeds, robotic arm movements, and assembly sequences.

This ability to learn continuously means your manufacturing processes become more refined with every production run, adapting to variations in raw materials, environmental conditions, and equipment wear patterns without any manual intervention.

2. Predictive Maintenance : Minimizing Downtime with AI-Driven Failure Prediction

Predictive maintenance represents a fundamental shift from reactive repair strategies to proactive equipment management. Traditional maintenance approaches, either fixing equipment after it breaks or scheduling routine servicing at fixed intervals, cost manufacturers billions in unnecessary downtime and premature part replacements. AI-powered predictive maintenance changes this equation entirely.

The technology works by continuously analyzing streams of sensor data from your factory equipment. Vibration sensors, temperature monitors, acoustic detectors, and pressure gauges feed information into machine learning algorithms trained to recognize subtle patterns that precede equipment failures. These AI systems can detect anomalies invisible to human operators a slight increase in bearing temperature, unusual vibration frequencies, or microscopic changes in operational efficiency.

You gain the ability to schedule maintenance precisely when needed, not before or after. A manufacturer using predictive maintenance on their CNC machines might receive an alert that a spindle bearing will likely fail within 72 hours, allowing them to order the replacement part and schedule the repair during a planned production gap. This approach has delivered documented results : companies report downtime reduction of 30-50% and maintenance cost savings of 20-40%.

The equipment failure prediction capabilities extend beyond individual machines to entire production lines, helping you understand cascading risks and prioritize maintenance activities based on actual business impact rather than guesswork.

3. Advanced Quality Control through Computer Vision Systems Powered by AI

Computer vision quality control has changed the way manufacturers find defects and keep product standards. Unlike traditional methods that depend on human workers to manually check products, an approach that's slow, inconsistent, and susceptible to errors caused by fatigue, AI-powered systems completely transform this situation.

These defect detection AI systems employ cameras and sensors to capture detailed images of products as they pass through production lines. In a matter of milliseconds, machine learning algorithms examine these images, spotting defects that might go unnoticed by humans. These systems are capable of detecting tiny cracks, color differences, size inconsistencies, and surface flaws with astonishing accuracy.

The benefits of automating product inspection go beyond just being accurate :

- Speed : AI systems can inspect hundreds of items every minute, far surpassing what humans can do

- Consistency : Algorithms maintain the same standards around the clock without any variation or decline in performance

- Scalability : You can implement these systems across multiple production lines without significantly increasing labor costs

- Data insights : Computer vision systems gather valuable quality data that helps identify recurring problems and areas for improvement in the process

Automotive manufacturers use these systems to check welds and paint finishes. Electronics companies employ them to verify circuit board assembly. Food processing plants make use of AI for factory automation to find contamination and packaging defects. This technology is flexible enough to adapt to almost any inspection situation where visual evaluation determines product quality.

4. Generative Design and Operations Optimization with AI Algorithms

Generative design manufacturing is reshaping how products come to life in modern factories. You feed AI algorithms with design parameters, material constraints, manufacturing methods, cost limitations, and performance requirements, and the system generates hundreds of optimized design alternatives.

This approach has proven transformative at companies like Airbus, where generative AI created a partition design that was 45% lighter than traditional versions while maintaining structural integrity.

The technology accelerates prototyping cycles from weeks to days. You can explore design possibilities that human engineers might never consider, discovering innovative solutions that balance weight, strength, and manufacturability. General Motors used generative design to consolidate eight separate components into a single part, reducing weight by 40% and eliminating assembly steps.

AI content creation extends beyond physical design into operational workflows. Production scheduling systems now use AI algorithms to dynamically adjust manufacturing sequences based on real-time demand signals, machine availability, and material inventory levels. You see this in action when AI-powered systems automatically reschedule production runs to accommodate rush orders without disrupting the entire manufacturing timeline.

Design automation tools integrate with supply chain management platforms, analyzing supplier lead times, transportation costs, and inventory turnover rates. These systems identify bottlenecks before they impact production, suggest alternative sourcing strategies, and optimize order quantities. You gain visibility across your entire operation, making data-driven decisions that reduce waste and improve throughput.

5. Real-Time Decision Making for Smarter Production Lines Using Autonomous Adjustments from Continuous Monitoring by AI Systems

Manufacturing environments generate massive amounts of data every second from temperature sensors to pressure gauges, from machine speeds to material flow rates. Real-time decision making transforms this constant stream of information into actionable insights that keep production lines running at peak performance.

Traditional manufacturing systems relied on human operators to monitor dashboards, interpret data, and make adjustments. This approach introduced delays, inconsistencies, and the inevitable human error factor. AI-powered systems eliminate these bottlenecks by processing data instantaneously and implementing corrections without human intervention.

Autonomous production adjustment capabilities allow AI systems to :

- Detect deviations from optimal operating parameters within milliseconds

- Adjust machine settings automatically to maintain product specifications

- Recalibrate equipment based on material variations or environmental changes

- Shift production priorities dynamically based on demand signals

You'll see tangible benefits in your output quality. When AI systems detect that a cutting tool is wearing down or that material consistency has shifted, they compensate immediately before defects occur. This proactive approach reduces scrap rates significantly. Some manufacturers report waste reduction of up to 30% after implementing AI-driven autonomous adjustments.

The speed advantage matters. While a human operator might take minutes to notice a problem and implement a fix, AI systems respond in real-time, preventing dozens or hundreds of defective units from being produced during that window.

6. Collaborative Robots (Cobots) : Enhancing Workforce Productivity Through Safe Human-Robot Teamwork In Factories

Collaborative robots represent a fundamental shift in how factories approach automation. Unlike traditional industrial robots confined behind safety cages, cobots factory automation systems are specifically engineered to share workspace with human operators. These machines incorporate advanced sensors, force-limiting capabilities, and sophisticated AI algorithms that enable them to detect human presence and adjust their movements accordingly.

The safety features built into cobots allow them to stop instantly when they encounter unexpected resistance or contact. You'll find these robots equipped with rounded edges, padded surfaces, and speed restrictions that prevent injury during accidental collisions. This design philosophy transforms the factory floor from segregated zones into integrated workspaces where humans and machines complement each other's strengths.

Tasks That Cobots Excel In

Cobots excel in handling tasks that drain human workers :

- Repetitive assembly operations : Tasks requiring consistent precision over extended periods

- Heavy lifting and material handling : Activities posing ergonomic risks to employees

- Pick-and-place activities : Operations in packaging and sorting applications

- Machine tending : Loading and unloading parts from CNC machines or injection molding equipment

- Quality inspection tasks : Activities requiring consistent attention to detail

Adaptive Learning : Enhancing Cobot Capabilities with AI

AI for factory automation enhances cobot capabilities through adaptive learning. These systems observe human operators, learn optimal movement patterns, and refine their performance without extensive reprogramming. You can redeploy cobots across different tasks by simply guiding them through new motions, making them remarkably flexible investments for manufacturers facing changing production demands.

7. Simulating Factory Operations with Digital Twin Technology Supported by Predictive Analytics for Enhanced Equipment Performance Planning In Manufacturing Environments

Digital twin technology manufacturing creates virtual replicas of physical equipment, production lines, and entire factory systems. These digital counterparts mirror real-world behavior by continuously ingesting data from IoT sensors, operational systems, and historical performance records. AI algorithms process this information to simulate how equipment will respond under various conditions, stress levels, and operational scenarios.

The predictive analytics capabilities embedded within digital twins allow you to test modifications, identify potential bottlenecks, and forecast equipment degradation before implementing changes on the actual factory floor.

You can run thousands of simulations in hours scenarios that would take months or be impossible to test in physical environments. When a manufacturer needs to adjust production parameters or introduce new machinery, the digital twin reveals the impact without risking costly downtime or product defects.

Key benefits span the entire asset lifecycle :

- Design phase : Engineers validate equipment configurations and layout optimization before installation

- Operational phase : Real-time monitoring detects anomalies and suggests performance improvements

- Maintenance planning : Predictive models determine optimal service intervals based on actual usage patterns rather than generic schedules

- End-of-life decisions : Data-driven insights inform replacement timing and refurbishment opportunities

You gain unprecedented visibility into equipment health, enabling maintenance teams to address issues during planned shutdowns rather than responding to unexpected failures that halt production.

8. Optimizing Supply Chain Management with Integrated AI Solutions Across All Stages from Demand Forecasting to Inventory Control In Modern Factories

Supply chain optimization AI is changing the way factories handle their entire logistics system. Now, you can use intelligent systems that look at past sales data, market trends, and outside factors like weather patterns or economic indicators to accurately predict demand. These forecasting tools powered by AI help you avoid expensive mistakes like producing too much or running out of stock, which are common problems in traditional manufacturing.

Demand Forecasting with AI

AI-powered forecasting tools help you avoid the costly mistakes of overproduction or stockouts that plague traditional manufacturing operations.

- Analyzing historical sales data

- Considering market trends

- Taking into account external factors like weather patterns or economic indicators

Inventory Management with Machine Learning

Machine learning algorithms continuously learn from your supply chain data, identifying patterns that human analysts might miss.

- Monitoring inventory levels in real-time

- Automatically triggering reorder points based on predicted consumption rates and lead times

This intelligent approach to inventory management reduces carrying costs while ensuring materials arrive exactly when production lines need them.

Order Fulfillment Optimization with AI

The automation extends to order fulfillment, where AI optimizes routing decisions for maximum efficiency.

- Determining the fastest picking routes

- Identifying optimal storage locations for products

Consider how Amazon's fulfillment centers use AI to determine the fastest picking routes and optimal storage locations for products. You can implement similar strategies in your factory, where AI analyzes order patterns and suggests warehouse layouts that minimize travel time and handling costs.

Energy Consumption Monitoring in Supply Chain Operations

Energy consumption monitoring represents another critical application.

- Tracking power usage across your supply chain operations

- Identifying opportunities to reduce costs during peak pricing periods

AI systems track power usage across your supply chain operations, identifying opportunities to reduce costs during peak pricing periods. You'll receive actionable recommendations for scheduling energy-intensive processes during off-peak hours, directly impacting your bottom line.

9. Data-Driven Workforce Management for Improved Employee Productivity and Shift Scheduling in Industry 4.0

Workforce optimization AI is changing how factories manage their most valuable asset : people. Modern manufacturing facilities generate large amounts of employee performance data, from task completion rates to quality metrics, that AI systems analyze to create smarter staffing strategies.

How AI-Powered Workforce Management Works

AI-powered workforce management platforms examine historical performance patterns, skill sets, and productivity trends to match the right employees with specific tasks. Here's how it works :

- Data Collection : The system gathers data on employee performance, including metrics such as task completion rates and quality scores.

- Analysis : AI algorithms analyze this data to identify patterns and trends in employee performance.

- Matching : Based on the analysis, the system determines which employees are best suited for particular tasks.

- Scheduling : The system automatically assigns employees to shifts where their expertise can have the greatest impact.

This data-driven approach eliminates guesswork from scheduling decisions and ensures that the right people are assigned to the right jobs.

Benefits of AI-Powered Workforce Management

Labor shortages are a major challenge facing manufacturing industries worldwide, making efficient resource allocation critical. AI for factory automation addresses this challenge by :

- Predicting peak production periods requiring additional staff

- Identifying skill gaps before they impact operations

- Optimizing shift rotations to prevent burnout and maintain consistent output

- Balancing workloads across teams to maximize utilization rates

These benefits can lead to significant improvements in labor productivity and cost savings for factories.

Real-World Results

Factories using AI-driven workforce analytics have reported impressive results :

- 15-20% improvements in labor productivity : By matching employees with tasks they excel at, these factories have seen significant increases in output.

- Reduced overtime costs : The technology analyzes factors like employee fatigue patterns and break timing to create schedules that minimize the need for overtime.

These outcomes demonstrate the potential of AI-powered workforce management to drive efficiency and worker well-being.

Continuous Learning and Improvement

One of the key advantages of AI systems is their ability to learn from outcomes. As these intelligent systems process more data about your workforce's capabilities and preferences, they continuously refine their recommendations.

This means that over time, the scheduling decisions made by the AI will become even more tailored to your specific workforce, resulting in further improvements in productivity and employee satisfaction.

Benefits and Challenges of Adopting AI in Factory Automation

The benefits and challenges of adopting AI in factory automation present a complex landscape for manufacturers.

Benefits of AI in Factory Automation

AI for factory automation delivers substantial cost reductions through :

- Decreased downtime

- Optimized resource allocation

- Minimized waste

You gain competitive advantages through :

- Faster time-to-market

- Improved product quality

- Enhanced operational flexibility

The technology also offers benefits such as :

- Accelerated innovation cycles

- Support for sustainability initiatives through precise energy management

Challenges of Implementing AI in Factory Automation

Implementation difficulties require careful consideration, including :

- Data quality issues that can undermine AI effectiveness

- Initial investment costs that create barriers, particularly for small and medium-sized manufacturers

- Cybersecurity vulnerabilities that expand as connected systems increase attack surfaces

- Skills shortages across the industry, with demand for AI specialists, data scientists, and technicians far exceeding supply

- Change management becoming critical as workforce adaptation determines whether AI investments deliver promised returns

To overcome these challenges, manufacturers must ensure clean, standardized information flowing from legacy systems, address initial investment costs through strategic partnerships or government support, implement robust cybersecurity measures, invest in training programs to bridge skills gaps, and actively involve employees in the change management process.

Conclusion

The changes happening in factories right now aren't just small improvements, they're completely rethinking how manufacturing works. AI technologies are proving their value in every part of production, from machine learning algorithms optimizing processes instantly to collaborative robots working safely with human teams.

You've seen how these innovations solve real manufacturing problems : predictive maintenance stops expensive unexpected shutdowns, computer vision systems catch defects that human inspectors might overlook, and digital twins let you test scenarios without risking actual equipment. The supply chain benefits alone, smarter demand forecasting, automated inventory management, optimized scheduling, can make AI investments worthwhile for many manufacturers.

The way forward requires careful planning. You'll need to weigh the undeniable benefits against real challenges like cybersecurity threats, skills shortages, and implementation costs. Success depends on seeing AI adoption as a long-term strategy rather than just buying a technology.

Manufacturing facilities that embrace these AI-driven capabilities will be better positioned to compete in an increasingly demanding market. The factories that will thrive five years from now are the ones that started their AI transformation today, learning through practical implementation and building the expertise needed to fully use these powerful tools.

The question isn't whether AI will change manufacturing, it already is. The question is whether you're ready to be part of that change.

FAQs (Frequently Asked Questions)

How does AI enhance efficiency and precision in factory automation ?

AI enhances efficiency and precision in factory automation by utilizing machine learning algorithms to analyze sensor and equipment data in real-time. This enables process optimization, reduces errors, and improves the accuracy of manufacturing operations, leading to higher productivity and product quality.

What is predictive maintenance and how does AI minimize downtime in manufacturing ?

Predictive maintenance involves forecasting equipment failures before they occur to avoid unplanned stoppages. AI leverages sensor data to accurately predict potential failures, enabling proactive maintenance actions that minimize downtime and extend equipment lifespan in manufacturing environments.

In what ways do AI-powered computer vision systems improve quality control in factories ?

AI-powered computer vision systems automate product inspections by detecting defects with greater accuracy and speed compared to traditional methods. These systems enhance quality assurance by continuously monitoring production lines, reducing human error, and ensuring consistent product standards.

How are generative design and AI algorithms transforming product design and operations optimization ?

Generative design uses AI algorithms to create innovative product designs by exploring numerous possibilities quickly. Additionally, AI optimizes operational workflows such as supply chain management and production scheduling, driving efficiency and flexibility in manufacturing processes.

What role do collaborative robots (cobots) play in enhancing workforce productivity ?

Collaborative robots, or cobots, work safely alongside human operators to perform repetitive or physically demanding tasks. By assisting the workforce, cobots increase productivity, reduce workplace injuries, and enable human workers to focus on more complex activities within factory automation settings.

What are the benefits and challenges of adopting AI in factory automation ?

Adopting AI in factory automation offers benefits like cost reduction, improved efficiency, enhanced decision-making, and innovation. However, challenges include implementation difficulties, cybersecurity risks, skills shortages, and the need for careful integration of intelligent systems such as machine learning algorithms and robotics technology into existing manufacturing processes.